Myths and Facts About Compressed Air

Compressors Myths and Facts

Myth: it is safe to clean dirt and debris from a work area using compressed air:

Myth: Variable speed drive is always the best solution for the most efficient part-load performance:

Myth: Variable speed drive increases oil carryover:

Myth: using a variable speed drive compressor eliminates the need for a flow controller:

Myth: All “Synthetic” compressor fluids are the same:

Myth: All Polyglycol(PAG) blended compressor fluids are the same:

Polyolesters (POE): POE’s handle heat very well and run varnish and sludge free. They are best known as jet engine lubricants. They are expensive and are used in applications where performance is critical, like in a rotary screw air compressor.

Diesters:

BEWARE, many generic Polyglycol/Ester blends turn out to be a Diester base with a minimum amount of Polyglycol. These generic fluids will have all the issues associated with a Diester fluid

Myth: Generic replacement parts and compressor lubricants are the same as manufacturer proprietary parts and lubricants:

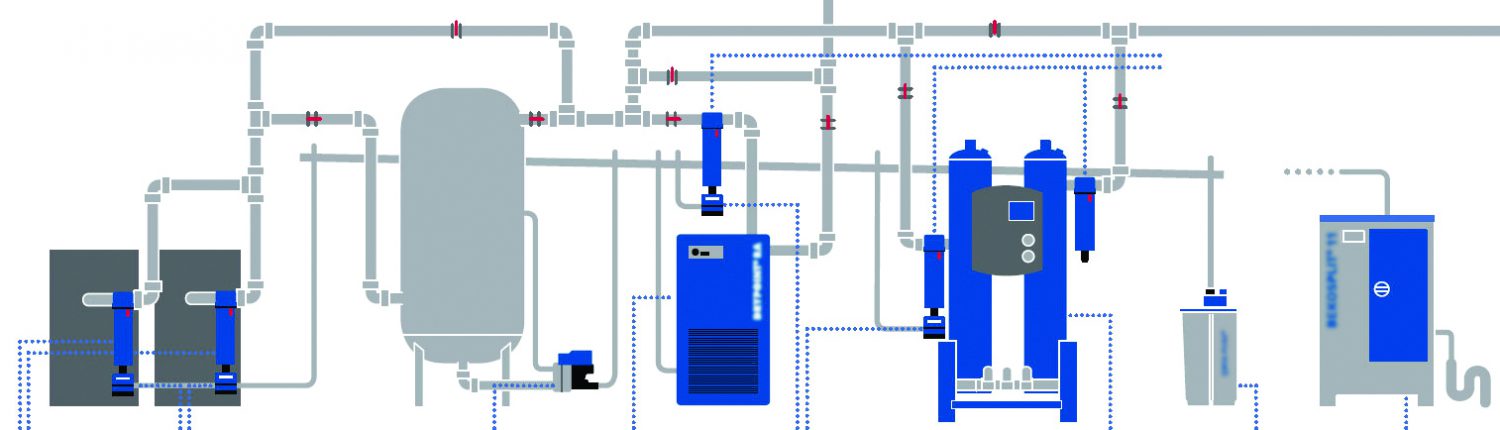

Air Treatment Myths and Facts

Myth: Filter elements should only be changed when differential pressure is high.

Myth: Coalescing filters are ONLY for oil removal

Fact: Coalescing filters have an even higher capture rate with solid contaminants than with liquids.

Myth: Oil contamination is not present in atmospheric air

Myth: Liquid oil and oil aerosol are the only contaminants present in a compressed air system.

The ten contaminants are:

- Water vapor

- Liquid Oil

- Oil vapor

- Rust Atmospheric Dirt

- Water Aerosols Microorganisms

- Oil Aerosols

- Liquid Water

- Pipe scale

Only two of these contaminants, liquid oil and oil aerosol are introduced by a lubricating compressor. The purification equipment required to reduce, or remove the remaining contaminants by virtue of their operation also remove liquid oil and oil aerosols. Therefore regardless of the type of compressor installed, purification equipment is required.

Myth: Compressed air contamination is a compressor issue

Source 1 – Atmospheric Air

Air compressors draw in huge amounts of atmospheric air, which continuously fills the system with contaminants such as water vapor, micro-organisms, atmospheric dirt and oil vapor.

Source 2 – The Air Compressor

In addition to the contaminants drawn in through the compressor intake, the compressor also adds additional wear particulates from its operation. Additionally, oil lubricated compressors carry over liquid oil, oil aerosols and oil vapor from the compression process. Once through the compression stage, the after-cooler will also condense water vapor, introducing it into the compressed air in both a liquid and aerosol form.

Source 3 – Compressed air storage devices

Source 4 – Compressed air distribution piping

The air receiver (storage device) and the system piping that distributes the compressed air around the facility both store large amounts of contamination. Additionally, they cool the warm, saturated compressed air which causes condensation on a large scale, adding liquid water into the system. This saturated air and liquid water leads to corrosion, pipe scale and microbiological growth.

Myth: Static Oil Water Separators are not suitable for synthetic lubricant:

Myth: Any dryer (refrigerated or desiccant) can be installed outdoors.

In the case where outside installation without roof is a necessity, request an outdoor modification package including freeze protection, UV protection in paint, fasteners and electronics, and Nema 4 components throughout. A Nema 4 electrical enclosure alone is not sufficient for an outdoor without roof installation.

Myth: Most dryers do not provide dryness levels to the same levels quoted in sales literature:

Myth: Compressed air filters also dry compressed air:

Note: For further clarification contact Sakoon service info@sakoon.com.pk