Compressed Air Systems – 10 Steps to Save Energy

The most expensive component in the total cost of compressed air is energy. In fact, over the lifespan of a typical compressor, energy typically costs several times more than the purchase price of the compressor. The bottom line, maximizing energy efficiency saves you money.

The first step to reduce compressed air energy costs is to measure and monitor your compressed air system’s energy consumption, flow rates and operating air pressure. Small adjustments can reduce your operating pressure and energy costs while improving flow rates and output. Here are 10 steps you can take to optimize your compressed air system and save energy costs.

1.Turn It Off.

2.Fix Existing Leaks.

A quarter-inch air leak at 100 psi will cost you more than PKR 262,037.00 a year. Pipe systems older than five years can have leaks of up to 25 percent. Because it takes energy to generate compressed air, any air that leaks is money wasted. Approximately 80 percent of air leaks are not audible, so to minimize these problems, third-party help in detecting these leaks may be a necessity.

3.Prevent New Leaks.

4.Reduce Pressure.

5.Check Drains

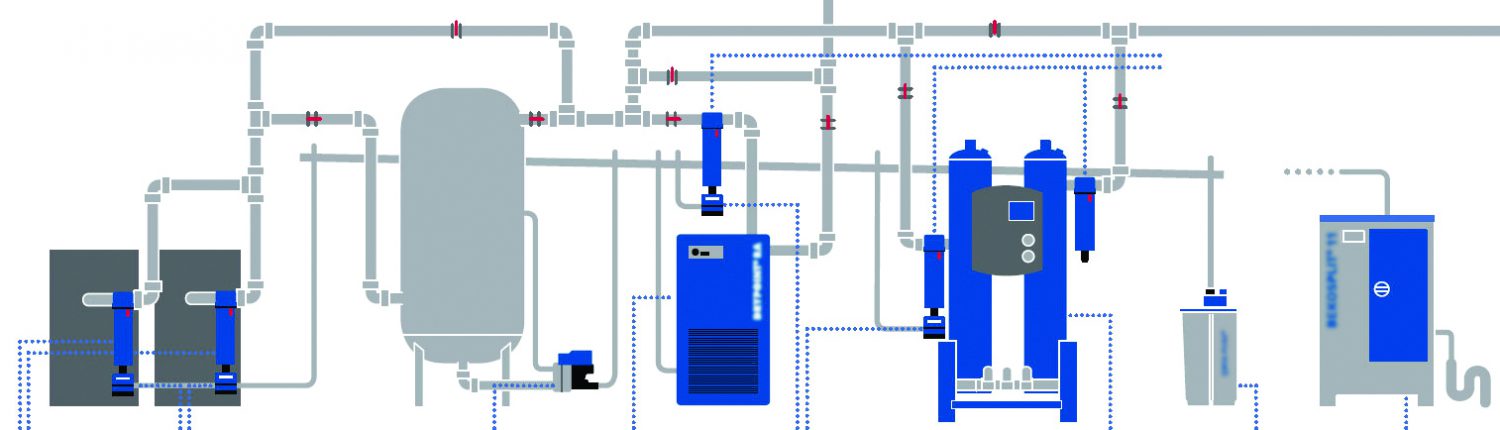

6.Review Piping Infrastructure.

7.Change Filters Systematically

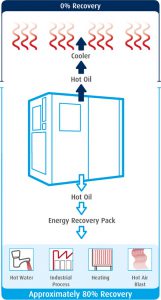

8.Recover Heat.