Transair Compressed Air Pipe Solutions in Perth

Quick assembly

More importantly, the fittings eliminate the need for special tools, pipe preparation and threading, as well as the time needed for soldering and the glue to dry. Once a Transair pipe is pushed into the fitting, the connection is secure and ready to be pressurised.

Various technologies also take into account the specific requirements of each diameter of pipe to provide you with an optimum safety factor, fast connection and highest flow.

In addition, Transair compressed air pipe offers an easy means of adding a new drop, secondary line or bypass onto an existing length of pipe, which is an important consideration for any compressed air pipe work system. Transair’s quick assembly brackets are designed for this purpose, eliminating the need to cut the pipe. A swan’s neck that is built into the brackets retains condensate water in the main line. Thanks to its small size, the Transair pipe quick assembly bracket facilitates new additions in the tightest spaces, and can be used for connecting horizontal branch lines and vertical drops whilst preventing the transfer of condensate from the main line.

Durable equipment, clean air quality

Transair pipes prevent problems that are caused by rust, which affect galvanized steel systems. Thanks to consistent clean air/water, Transair aluminium and stainless steel compressed air pipes ensure the extended longevity of equipment, and can help you to avoid frequent changes of filter elements.

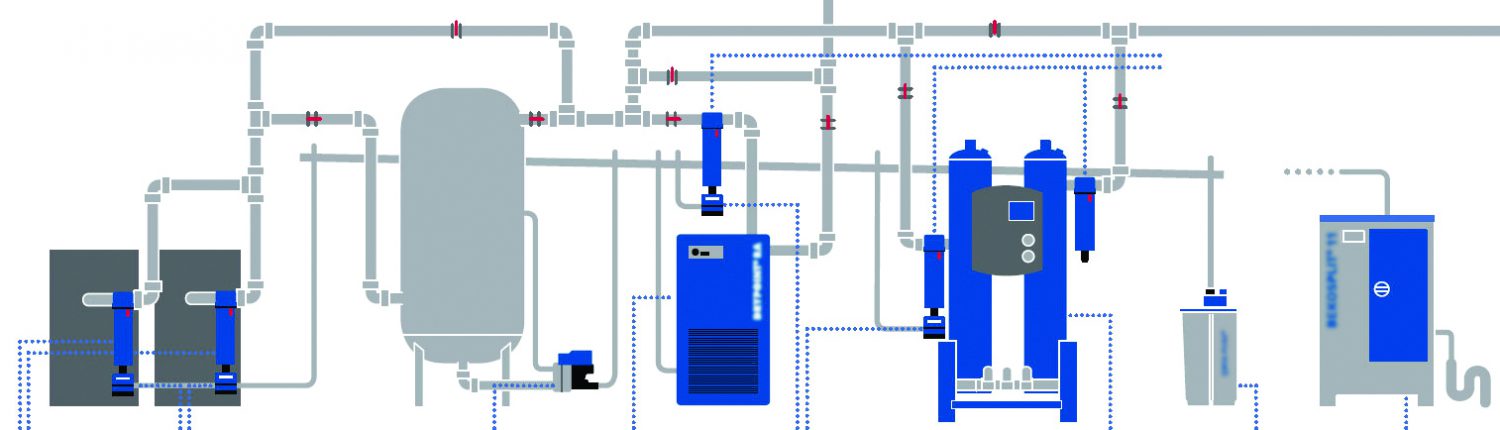

Transair pipes for compressed air, gases and vacuum transfer applications

Transair compressed air pipe systems meet the requirements of numerous industries – aerospace, electronics, pharmaceutical, medical, plastics extrusion, manufacturing, power generation, automotive and garage workshop installations. The Transair pipe product line is sophisticated enough for NASA, while also being easy and affordable enough for a home garage.

- Clean and safe site conditions: Assembly without welding or gluing

- Prevention of leaks: Mechanical connection without a permanent crimp

- Reduced assembly time: Pipes and connectors supplied ready for immediate installation

- Easier handling: Ground level preparation plus lightweight portable tools

- Network quickly in use: Immediate Start-up

Optimum efficiency for machinery and tools

Example:

A 63mm Transair pipe system gives a flow performance that is better than that of a nominal (2 ½’’) galvanized steel system.

Transair aluminium compressed air pipes ensure superior flow performance over a longer period of time.

Example:

The inner bore of a steel pipe could corrode by 40% over its lifetime. A Transair pipe maintains its smooth bore throughout its lifetime.