Leaks can be a significant source of wasted energy in an industrial compressed air system, sometimes wasting 20-30% of a compressor’s output. A typical plant that has not been well maintained will likely have a leak rate equal to 20% of total compressed air production capacity. On the other hand, proactive leak detection and repair can reduce leaks to less than 10% of compressor output.

We Detect and Fix Your Compressed Air Leaks – Ensuring Energy Efficient System

Common Leak Problem Areas

- Control and shut-off valves

- Couplings, fittings, hoses and tubes

- Cylinder rod packing

- Disconnects, especially if they are worn or missing 0-rings

- Filters, lubricators and regulators

- Flanges

- Leaking or botched drains

- Open blow-offs

- Open condensate traps

- Pipe joints

- Point-of-use devices

- Thread sealants

- Worn seals or gaskets

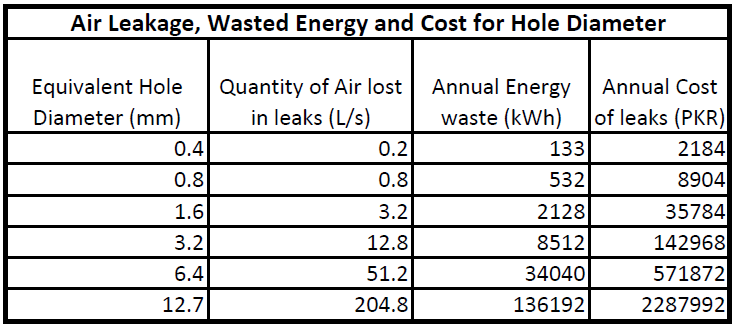

Leakage Cost

Opt for our leakage management program and make your system more energy efficient.

Consult our Compressed Air expert for leak management program.