Aluminium Piping Solutions For Compressed Air, Vacuum, Liquid And Inert Gas Applications

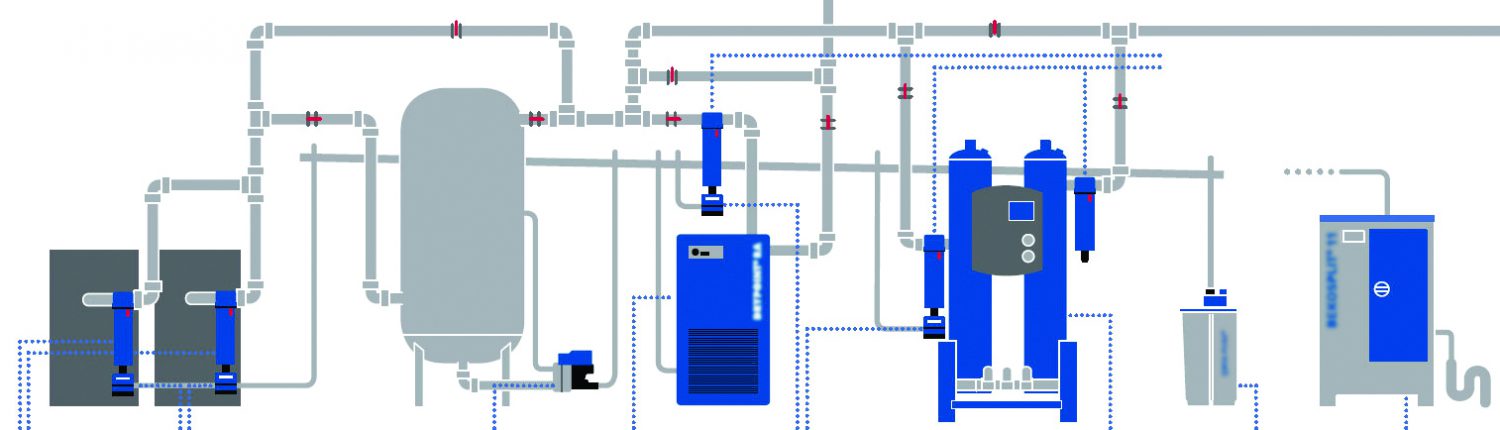

The Transair solution

Quick assembly, durability, superior performance, reduced running costs and maximum energy efficiency.

Quick assembly

AirPro’s aluminium and stainless steel pipe systems are ready to assemble and easy to modify.

AirPro piping is easier and lighter to lift and handle than standard steel piping, and its push-to-connect fittings secure connections instantly. The fittings eliminate the need for special tools, pipe preparation and threading.

AirPro also eliminates the time needed for soldering and for glue to dry. Once the pipe is pushed into the fitting, the connection is secure and ready to be pressurized.

Lastly, various technologies take into account the specific requirements of each diameter of pipe and provide you with an optimum safety factor, fast connection and highest flow.

We also offers an easy means of adding a new drop, secondary line or bypass, onto an existing length of pipe which is an important consideration for any air pipe work system. Transair quick assembly brackets are designed for this purpose, without the need to cut the pipe. A swans neck built into the brackets retains condensate water in the main line. Thanks to its small size, the Transair quick assembly bracket facilitates new additions in the tightest spaces and can be used for connecting horizontal branch lines and vertical drops whilst preventing the transfer of condensate from the main line.

Durable Equipment, Clean Air Quality

AirPro aluminium and stainless steel pipe systems ensures a total absence of corrosion (self protection by formation of aluminium oxide). The inner pipe surface consistently delivers clean compressed air, inert gas, and chilled water (stainless steel only). Transair also protects industrial equipment against condensates transfer thanks to its quick assembly brackets with integral upward loop.

Aluminium piping prevents the problems caused by rust, which affects galvanized steel systems. Thanks to consistent clean air/water, AirPro aluminium pipe ensures extended longevity of equipment and can help to avoid frequent changes of filter elements.

Overall savings: reduction of installation, operating and commissioning costs

Example:

• Galvanized/Black steel installation: 2 metres per hour

• Copper installation: 2.5 metres per hour

• Transair installation: 13.5 metres per hour

All modifications or extensions to a Transair system can be completed extremely quickly and will meet your production requirements due to very short downtime periods.

Example:

• Lateral dismantling of pipe: 1 minute 30 seconds

• Drilling of pipe: 2 minutes 30 seconds

• Mounting Brackets: 45 seconds

• Remounting of pipe to the system: 1 minute 30 seconds